The raw material is nylon salt. Commonly known as "AH-Salt," it is supplied by tanker trucks from our plants in Belle-Etoile (Lyon, France) and Chalampé (Alsace, France) and is the basic building block for the manufacture of polyamide 66 fibres.

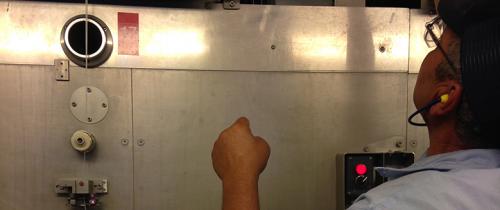

Through a continuous process (24/7), this salt is first concentrated by evaporation, then polymerized under high pressure and temperature. The polymer – similar to a “hot & highly viscous paste” – is then directly injected in spinnerets, through thousands of microscopic holes. Once the polymer comes out from the spinnerets, it is quickly cooled down by air, then water and goes from the viscous to the solid state. Here the filaments are born and we leave the “chemical world” to enter the physical, “textile” one.

Those thousands of filaments are gathered together as “cables” and then stretched in another workshop, on five different drawing lines. On those lines the filaments are first stretched to align the microscopic chains of polyamide and give the filaments dimensional stability. This cable can be left as is to produce tow for flock, crimped to produce nonwoven, textile or flooring articles, then finally cut (staple fibers) or not (crimped tow for textile high end specialties).

Tow for flock is packed in American boxes, other products are compressed and packed in bales, to save logistics costs.