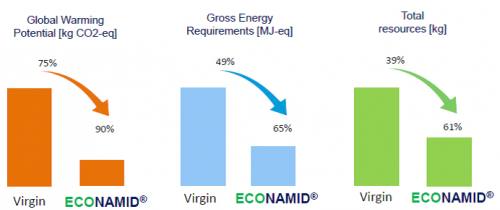

DOMO Engineering Plastics presented the new Life Cycle Assessment carried out in collaboration with the company LC Engineering, on the Econamid® product range.

At the conference, Domenico Lo Curto, new business development manager of DOMO Engineering Plastics, explained the environmental benefit achieved by the utilization of DOMO’s recycled PA6 and 6.6 products produced in the Arco (Italy) production plant, branded Econamid®, in comparison to their virgin equivalents and aluminum sheets.The study focused on the comparison of 4 grades: unfilled and 30% glass fiber reinforced polyamide 6 and 6.6. The Environmental figures presented refer to 1 kg delivered packed product. Generic data used to carry out the inventory analysis come from a commercial database as Ecolnvent v2.2 or from Eco profiles released by association of products as Plastics Europe 2005 for PA6 and PA6.6.