With more than 20 years’ experience in the compounding industry, DOMO Engineered Materials has cemented its position as a global expert in customized PA6 and PA66 solutions for agriculture, outdoor power equipment and small engine components.

In agriculture, two customized DOMONYL™ grades based on PA6, 33% glass fiber reinforced with different features, that provide improved performance in several structural applications are: DOMONYL™ 1850R33T1U2 Gy-426, a glass reinforced and UV stabilized PA6, custom colored for use in foot wells and footrests and DOMONYL™ 1850R33T1H1 Bk-7, a similar product with improved UV stabilization used in tread plates and other high-abuse applications.

“Supporting our customers with design services, such as mold filling and warp analysis performed by our Autodesk Silver Certified technical service team helps them to shrink their development timeline, bringing products to market faster,” said Wayne Gromowski, New Business Development Manager at DOMO Engineering Plastics, US.

“Agriculture and turf machine production as well as construction and forestry machines are one of DOMO’s core end markets and have been part of our strategic growth plans for over a decade and the diversification of our business, both in product line and customer base, forces us to think outside the box and develop application specific compounds for a variety of industries, as opposed for force-fitting an application into a standard grade,” added Rob Schultz, Domo’s Director of North American Operations.

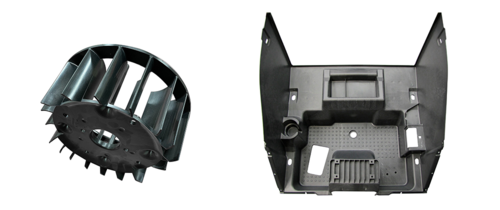

A solution for gasoline engine components in small and medium sized power equipment is DOMONYL™ 2120R16H BK, a customized, 16% glass fiber reinforced PA66 for use in small engine flywheels for lawn equipment, portable power generation, and snow throwers, providing improved stiffness, thermal stability, and optimal surface aesthetics.

“Our willingness to tweak filler loading levels is a very simple example of the customizations we can make to identify the best ‘material property to application’ relationship” continued Gromowski, Business Development Manager for DOMO US. “The foundation of technical service and custom compounding is to identify the property set that provides the best overall application quality at a competitive cost, then develop a formula that repeatedly produces that property set. It does not mean forcing the customer to choose from one bucket or another. The suppliers who are willing to listen to customers and customize solutions are the suppliers that customers will continue to work with.”

These products are developed at DOMO’s Buford, Georgia plant, acquired and integrated into the company in 2015. With a core business focused on PA6 and PA66 the facility produces many products exclusively for the North American market - matching custom compounds to custom part requirements.

From February 2022, DOMO will commercialize the historical TECHNYL®* brand in US, opening the doors to many innovation possibilities thanks to its PA6 and PA66 advanced product portfolio.

* TECHNYL® is a trademark of DOMO. TECHNYL® is exclusively developed and sold by DOMO in the EEA, Switzerland and, from February 2022, also in all other global regions.