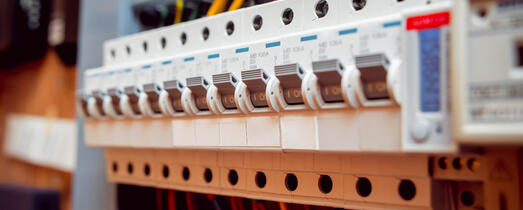

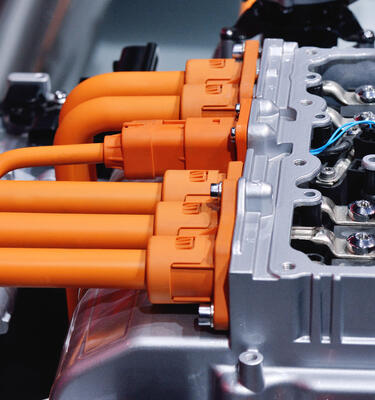

TECHNYL® ONE is a halogen-free high temperature polyamide optimized for electrical protection devices, power management equipment, automotive electrics and consumer electronics. Available in a full range of grades to meet demanding customer requirements, the flame-retardant halogen-free polymer nylon demonstrates best-in-class performance. TECHNYL® ONE is an innovative generation of halogen-free polymer resins addressing major challenges in electrical equipment for energy management and building automation such as safety, miniaturization and increased productivity.

Electrical equipment and consumer electronics manufacturers are increasingly looking to high-performance polyamides for device miniaturization while also meeting ever-more stringent industry regulations, including for fire and safety hazards. With its superior flowability and high-temperature matrix, as well as excellent electrical properties and halogen-free flame retardant performance, TECHNYL® ONE has clearly demonstrated its suitability for demanding applications within the electrical protection segment.